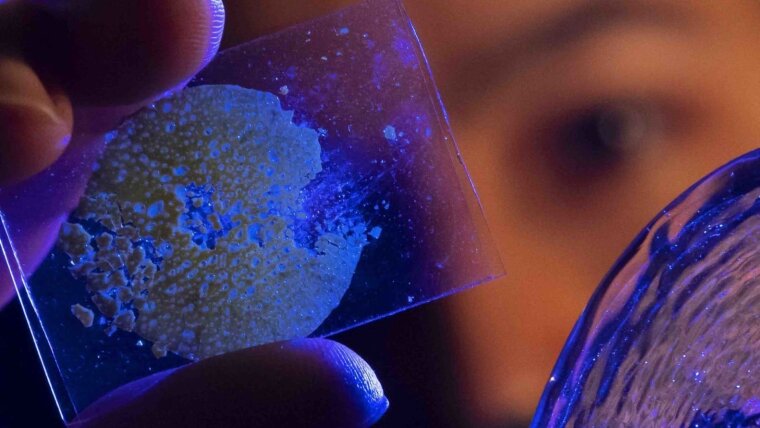

A team of materials scientists from Jena and Cambridge develops hybrid glass materials with novel combinations of properties. The researchers are combining organometallic and inorganic glass to produce composite forms of glass that are impact-resistant and break-proof like plastic while retaining the hardness of glass.

By Ute Schönfelder

Composites of organic and inorganic materials are a common phenomenon in nature. For example, bones consist of collagen (an organic structural protein) and apatite (an inorganic mineral) what makes bones flexible yet strong. Composites enable combinations of properties that could not be achieved with just one type of material.

When it comes to producing hybrid materials with such properties, however, the natural creation of such technological materials is still far superior; the artificial production of similarly functional hybrid materials is still a major challenge today. However, a team of researchers from the Universities of Jena and Cambridge have succeeded in producing a new new class of hybrid glass materials that combine organic and inorganic components that gives the materials very special mechanical properties. They have achieved this using combinations of materials in which organometallic and inorganic glasses are chemically bonded. The researchers have presented their work in the renowned journal ›Nature Communications‹.

Organometallic framework as the basic structure of the new material

In recent years, an increasing amount of research has been conducted into materials consisting of metal-organic frameworks (or MOF materials for short). They can be used, for example, as separating diaphragms, for storing liquids and gases, as catalyst supports, and for storing electrical energy.

The advantage of MOF materials is that their framework structures can be configured in a targeted manner, from the length scale of individual molecules up to a few nanometers. In this way, for example, the porosity achieved can be adapted to a large number of applications, both in terms of the size of the pores and their permeability, and in terms of the chemical properties prevailing on the pore surfaces.

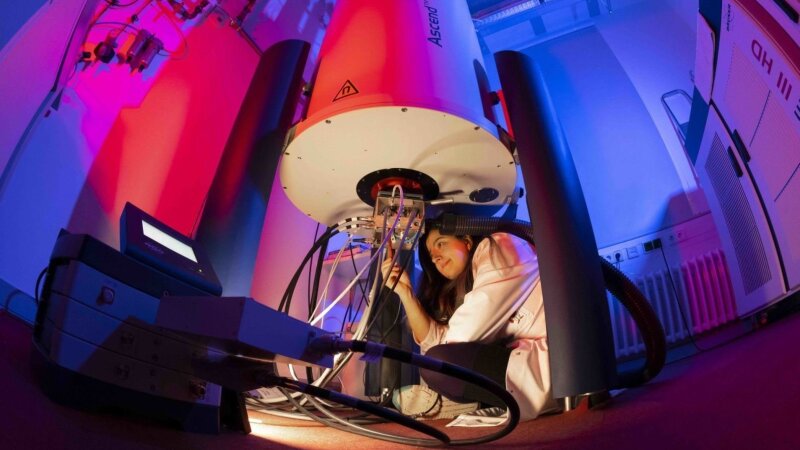

»The chemical design of MOF materials follows a modular principle, according to which inorganic nodes are connected to one another via organic molecules to form a three-dimensional network,« explains Louis Longley from the University of Cambridge. This results in an almost infinite variety of possible structures, some of which could be transformed into a glassy state through heat treatment. »While crystalline MOF materials are typically synthesized in powder form, the liquid and glass states open up a wide range of processing options and potential shapes«.

»By combining MOF-derived glass with classic, inorganic glass materials, we can get the best of both worlds,« says Courtney Calahoo from the University of Jena.

New properties created through chemical bonding with inorganic glass

Such composite glass has much better mechanical properties than previous types of glass, as it combines the impact resistance and fracture toughness of plastics with the hardness and rigidity of inorganic glass.

These properties are ensured by the fact that the materials involved are not simply mixed with one another, but real chemical bonds are formed in the contact area between the metal-organic frameworks and conventional glass. »This is the only way to create truly new properties, such as electrical conductivity and mechanical resistance,« adds Prof. Dr-Eng. Lothar Wondraczek, the glass chemist who led the study at the University of Jena.

Original Publication:

Metal-organic framework and inorganic glass composites. Nature Communications (2020), DOI: 10.1038/s41467-020-19598-9External link